TL;DR Summary

|

Metric |

Detail |

|---|---|

|

Industry |

Medical Device Manufacturing (FDA-regulated) |

|

Challenge |

FDA-compliant Electronic Batch Records across weigh/dispense through tertiary packaging |

|

Solution |

|

|

Timeline |

24 months (2017 selection → 2019 full value realization) |

|

Daily Paper Elimination |

1,800 pages (150 production orders × 12 pages average) |

|

Changeover Improvement |

66% faster (15 minutes → 5 minutes) |

|

Compliance Achievement |

Full |

|

Additional Benefits |

Reduced mislabeling incidents, improved traceability, data-driven continuous improvement |

The Extreme Vertical Integration Challenge

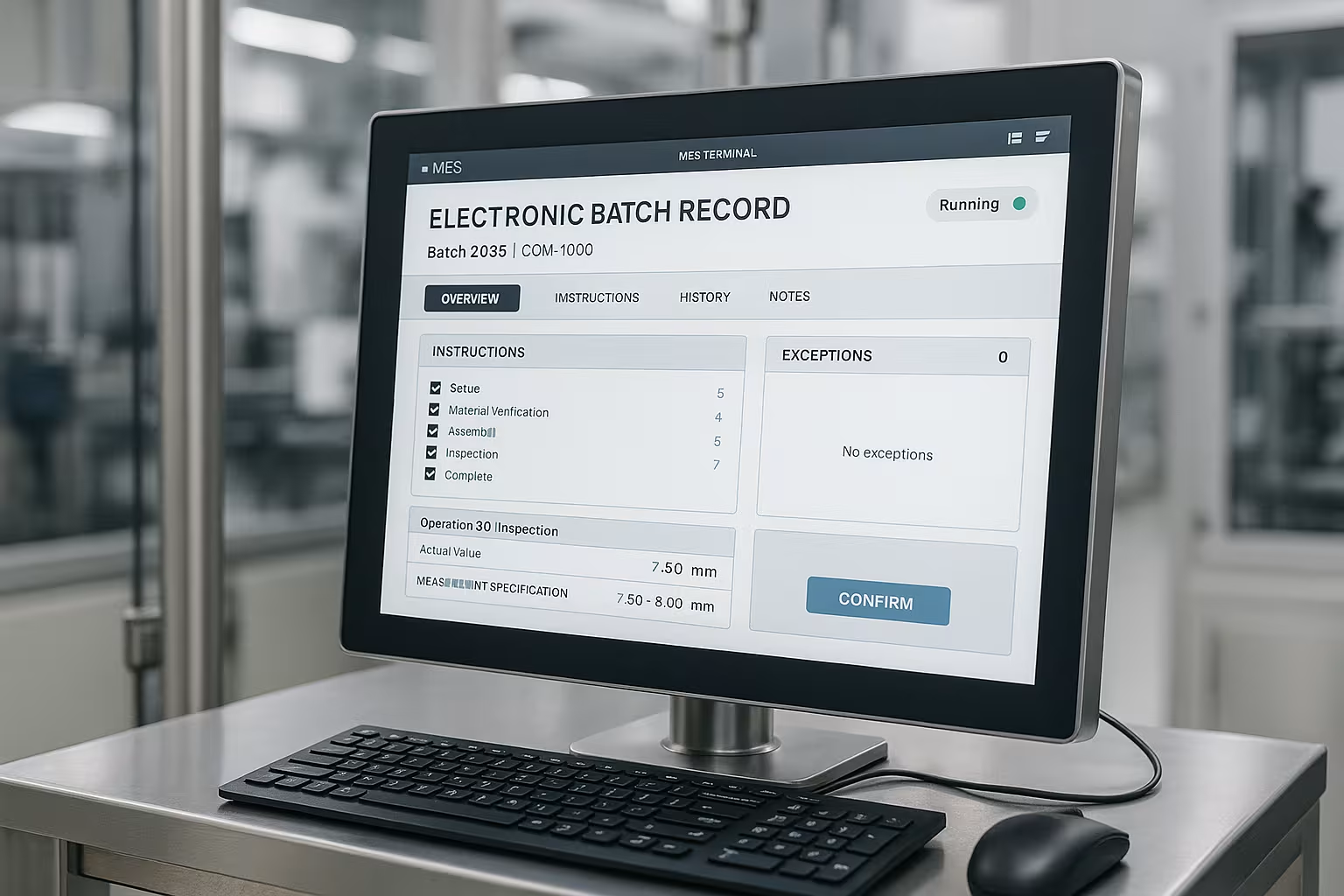

Most medical device manufacturers face complex regulatory requirements, but few grapple with the compliance challenges of extreme vertical integration. This case study examines how a leading dental products manufacturer successfully implemented Critical Manufacturing MES across their complete value chain, from raw material weigh and dispense operations through injection molding, filling, label printing, and multiple levels of packaging operations.

Unlike typical medical device companies that outsource significant portions of their manufacturing, this organization performed all operations in-house. This vertical integration strategy provided operational control and quality assurance benefits, but created unprecedented complexity for FDA compliance and Electronic Batch Record (eBR) implementation.

Quantified Pain Points

Before MES implementation, the manufacturing operation generated 1,800 pages of paper batch records daily across 150 production orders. Each batch record averaged 12 pages of documentation covering the complete manufacturing process from raw materials through finished goods packaging.

- Compliance Risk: Illegible handwritten updates created potential FDA audit findings

- Operational Inefficiency: 15-minute changeovers between product runs due to manual documentation requirements

- Double Signature Requirements: Manual processes required duplicate approvals for

CFR 21 Part 11compliance - Storage Overhead: Physical scanning and archival of thousands of paper documents monthly

- Limited Visibility: Paper-based systems prevented real-time process monitoring and data analysis

Manufacturing Complexity Scope

The extreme vertical integration encompassed the complete dental products value chain:

- Weigh and Dispense: Raw material preparation with lot tracking requirements

- Formulation: Chemical mixing processes with strict FDA documentation mandates

- Injection Molding: Plastic component manufacturing with quality checkpoints

- Filling Operations: Product packaging with volume and weight validation

- Label Printing:

Zebra printing technologyintegration for compliance labeling - Secondary Packaging: Multi-product kitting and bundling operations

- Tertiary Packaging: Final shipping preparation with full traceability requirements

The CFR 21 Part 11 Compliance Imperative

Traditional paper-based batch records could no longer meet evolving FDA requirements for electronic records and electronic signatures. The organization needed a validated MES system that could eliminate double signatures while maintaining complete traceability across their complex manufacturing environment.

Technical Requirements Analysis

The MES solution needed to capture information from multiple sources across the manufacturing spectrum:

-

Man

-

Operator interactions and validated electronic signatures at each critical process step

-

Machine

-

OPC-UAintegration with shop floor devices and sensors for automated data collection -

Method

-

Step-by-step process instructions with enforced sequences and quality checkpoints

-

Material

-

Complete lot tracking and genealogy from raw materials through finished goods

-

Measurements

-

Quality data collection with real-time analysis and exception handling

Integration Architecture Requirements

The selected MES platform needed seamless integration with existing enterprise systems:

Oracle eBusiness Suitefor ERP functionality and financial integrationAgile PLMfor product lifecycle management and engineering changesOPC-UA devicesfor real-time shop floor data collectionZebra printing technologyfor automated label generation and compliance- Quality management systems for

CFR 21 Part 11audit trail requirements

MES Selection: Why Architecture Mattered

The 2017 MES selection process evaluated multiple enterprise-grade manufacturing execution platforms. Critical Manufacturing MES emerged as the optimal choice based on three critical factors: functional fit, modern architecture, and economic viability.

Selection Criteria and Evaluation

Critical Manufacturing MES differentiated itself from competitors through:

- Modular Design: Configurable system architecture that internal IT DevOps teams could learn and extend

- Integration Capabilities: Native connectivity to

Oracle EBS,Agile PLM, and industrial automation systems - Regulatory Compliance: Built-in

CFR 21 Part 11functionality with validated electronic signatures - Scalability: Ability to handle extreme vertical integration complexity within a single MES instance

- Economic Model: Competitive total cost of ownership for multi-million dollar implementation

Technical Architecture Decision

The decision to implement a single MES instance across all manufacturing operations represented a significant technical and business risk. However, this approach was essential for maintaining end-to-end traceability across the vertically integrated value chain while minimizing system complexity and maintenance overhead.

Implementation Strategy: From Waterfall Planning to Agile Execution

The implementation followed a hybrid methodology combining waterfall planning for infrastructure with agile development for MES recipe creation and testing.

Phase 1: Waterfall Foundation (2017-2018)

Initial implementation focused on infrastructure and core system capabilities:

- MES Environment Setup: Development, test, and production environment instantiation

- Integration Architecture: Connectivity frameworks for

Oracle EBS,Agile PLM, and shop floor systems - Security Framework:

CFR 21 Part 11compliance controls and electronic signature validation - Master Data Management: Product hierarchies, routing definitions, and quality specifications

Phase 2: Agile MVP Development (2018-2019)

Recipe development and pilot implementation utilized dedicated agile teams:

Internal Team Structure

- 2 MES Modelers: Specialized in translating physical processes to digital recipes

- 2 MES Developers: Custom extension development and integration coding

- 1 Solutions Architect/Product Owner: Technical requirements and sprint planning

- 1 Project Manager/Scrum Master: Agile methodology and stakeholder coordination

External Support Team

- 2 MES Developers: Additional development capacity for complex integrations

- 1 Project Manager: Vendor coordination and escalation management

Phase 3: DevOps Transition (2019+)

Following successful pilot validation, the internal DevOps team assumed ownership of ongoing development cycles, enabling continuous improvement and scaling to additional product lines.

The Critical Success Factor: MES Modeling Expertise

The most significant lesson learned from this implementation was the critical importance of MES modeling as a specialized skill set. Traditional IT developers and business analysts could not effectively translate complex manufacturing processes into digital MES recipes without dedicated training and experience.

MES Modeler Skill Requirements

Successful MES modelers needed expertise across multiple domains:

-

Product Knowledge

-

Deep understanding of dental product formulations, manufacturing specifications, and quality requirements

-

Manufacturing Process Expertise

-

Hands-on experience with weigh/dispense, formulation, injection molding, filling, and packaging operations

-

Quality Systems

-

FDA compliance requirements, quality checkpoints, and exception handling procedures

-

MES Technology Platform

-

Technical proficiency with

Critical Manufacturing MESconfiguration, recipe development, and integration capabilities

Team Development Strategy

"MES modelers are a specialized skill that must know products, manufacturing processes, quality, and the MES technology very well. The team must be dedicated to MES and nothing else during implementation. Prepare the next generation of modelers 6 months in advance of when you expect them to be productive."

This insight proved crucial for scaling beyond the initial pilot. Organizations planning similar implementations should invest in MES modeling capability development well before technical implementation begins.

Translating Physical Processes to Digital Recipes

The most technically challenging aspect of the implementation involved converting 12-page paper batch records into comprehensive MES recipes that captured all required information in the correct sequence and format.

Recipe Development Methodology

Each manufacturing process required detailed analysis and digital transformation:

- Process Mapping: Document current state workflows with decision points and quality gates

- Data Requirements Analysis: Identify all manual and automated data collection points

- Integration Point Definition: Specify connections to

Oracle EBS,Agile PLM, and shop floor devices - Exception Handling Design: Define workflows for quality failures and process deviations

- Electronic Signature Mapping: Implement

CFR 21 Part 11approval workflows

Technical Implementation Challenges

Several technical hurdles required innovative solutions:

- Legacy System Integration: Bridging modern MES capabilities with existing

Oracle EBSandAgile PLMsystems - Real-time Data Collection:

OPC-UAconnectivity to diverse shop floor equipment and sensors - Print Integration: Automated label generation through

Zebra printing technologywith variable data - Multi-level Packaging: Maintaining lot genealogy across secondary and tertiary packaging operations

Implementation Results and Business Impact

The MES implementation delivered measurable improvements across operational efficiency, quality, and regulatory compliance dimensions.

Operational Excellence Metrics

|

Metric |

Before MES |

After MES |

Improvement |

|---|---|---|---|

|

Daily Paper Documentation |

1,800 pages |

0 pages |

100% elimination |

|

Production Changeover Time |

15 minutes |

5 minutes |

66% reduction |

|

Documentation Errors |

Illegible handwriting |

Electronic validation |

Error elimination |

|

Signature Requirements |

Manual double signatures |

Electronic signatures |

CFR 21 Part 11 compliance |

|

Data Analysis Capability |

Manual paper review |

Real-time digital mining |

Continuous improvement enablement |

Quality and Compliance Improvements

Beyond operational efficiency gains, the MES implementation delivered significant quality and compliance benefits:

- Mislabeling Reduction: Automated label generation eliminated manual printing errors

- Enhanced Traceability: Complete lot genealogy from raw materials through finished goods

- Real-time Quality Monitoring: Immediate identification and response to process deviations

- Audit Readiness: Electronic records with complete audit trails for FDA inspections

Timeline to Value Realization

The implementation followed a predictable value realization pattern:

-

Year 1 (2018):

-

Pilot validation and process refinement with limited production volume

-

Year 2 (2019):

-

Full operational value realization as sufficient volume flowed through the MES system

-

Year 3+ (2020+):

-

Continuous improvement and scaling to additional product lines and manufacturing areas

Scaling Strategy and Current State

Following successful pilot validation, the organization systematically expanded MES coverage across similar production lines with product variants.

Initial Scope and Expansion

The initial implementation targeted end-to-end processes representative of 80% of products shipped. This strategic scope selection ensured maximum impact while managing implementation complexity and risk.

Subsequent phases expanded coverage to:

- Similar production lines with minor process variations

- Related product families with shared manufacturing steps

- Custom and low-volume products requiring specialized handling

Digital Transformation Portfolio Integration

The MES implementation represented one component of a broader multi-million dollar digital transformation portfolio that included:

- Enterprise resource planning system optimization

- Product lifecycle management enhancement

- Advanced analytics and business intelligence capabilities

- Supply chain planning and execution improvements

Lessons Learned and Implementation Guidance

This implementation provided valuable insights for other medical device manufacturers considering similar MES initiatives.

Critical Success Factors

- Invest in MES Modeling Expertise: The most important technical skill for implementation success

- Dedicated Implementation Teams: No part-time participation during core development and testing phases

- Plan for Complexity: Extreme vertical integration requires specialized approaches and extended timelines

- Change Management Focus: Comprehensive training and adoption support across diverse manufacturing areas

What Would Be Done Differently

Retrospective analysis identified several optimization opportunities:

- Earlier Modeler Development: Begin MES modeling training 6 months before productive contribution expectations

- Enhanced Change Management: Greater emphasis on organizational adoption across varied manufacturing environments

- Phased Integration Testing: More extensive integration testing with legacy systems before production deployment

Risk Mitigation Strategies

Key risk mitigation approaches that contributed to success:

- Dedicated Teams: Full-time commitment from internal and external resources during critical phases

- Incremental Validation: Thorough testing and validation before scaling to additional production lines

- Executive Sponsorship: Strong leadership support for multi-million dollar investment and organizational change

- Vendor Partnership: Close collaboration with

Critical Manufacturingfor complex integration requirements

Strategic Implications for Medical Device Industry

This implementation demonstrates how medical device manufacturers can successfully navigate the growing complexity of FDA compliance while improving operational efficiency through strategic MES deployment.

Industry Trends and Drivers

Several industry dynamics make similar implementations increasingly critical:

- Regulatory Evolution: FDA increasingly demanding electronic compliance and data integrity

- Supply Chain Resilience: Global disruptions highlighting need for enhanced traceability and visibility

- Competitive Pressure: Operational efficiency requirements for cost competitiveness

- Quality Expectations: Rising patient safety standards and zero-defect manufacturing goals

Implementation Methodology Applicability

The lessons learned from this extreme vertical integration implementation apply broadly to medical device manufacturers facing similar challenges:

- Complex manufacturing environments with multiple process types

- Strict FDA compliance requirements for electronic records

- High-volume production with extensive documentation needs

- Integration requirements with existing enterprise systems

Return on Investment Considerations

While specific financial details remain confidential, the quantified operational improvements demonstrate clear ROI through:

- Reduced labor costs for documentation and changeover activities

- Improved quality and reduced scrap through real-time process control

- Enhanced regulatory compliance and reduced audit risk

- Data-driven continuous improvement capabilities

Conclusion and Next Steps

This case study demonstrates that medical device manufacturers can successfully implement MES solutions across extreme vertical integration environments while achieving full CFR 21 Part 11 compliance. The key to success lies in recognizing MES modeling as a specialized skill, investing in dedicated implementation teams, and maintaining focus on measurable business outcomes.

Organizations considering similar implementations should prioritize MES modeling capability development, establish dedicated project teams, and partner with experienced implementation specialists who understand the unique challenges of vertically integrated medical device manufacturing.

"The combination of extreme vertical integration and FDA compliance requirements creates implementation challenges that require specialized expertise and proven methodologies. Success depends on understanding that MES modeling is a distinct technical discipline requiring dedicated focus and investment."

For medical device manufacturers struggling with similar challenges around electronic batch record implementation, FDA compliance, or MES selection for complex manufacturing environments, expert guidance can help avoid the common pitfalls that derail 60% of similar initiatives. The investment in proper planning, team development, and implementation methodology pays dividends through improved compliance, operational efficiency, and competitive advantage.